Waverley in Dry Dock - Third Report

Pictures by Gavin Stewart, words by Stuart Cameron

The new port paddle shaft arrived in Greenock from the Rolls Royce machine shop in Fife during the third week of Waverley’s overhaul at Garvel Drydock and soon afterwards it was offered up to the port wheel for trial fitting. The view below shows the paddlewheel with the shaft almost in position – the weight of this whole assembly is approximately 11 tonnes.

The old paddle shaft, which has served the ship well for almost 6 decades is seen in the picture below. The flange closest to the camera connects to the engine and the smooth surfaced section of the shaft is the part that crosses the main deck (under the engine alleyway steps) and sits in the paddle shaft bearing where it is lubricated by tallow. The section of the shaft that is slotted is the part that passes through the bobbin (hub) of the paddle wheel. The slots accommodated the ‘keys’, rectangular metal bars that prevent the wheel from slipping on the shaft when it is being driven by the engine.

Another view of the new paddle shaft in situ in the paddle wheel on the side of Garvel drydock before fitting in the ship

The outboard end of the paddle shaft is threaded to accommodate a huge nut that holds the wheel onto the shaft. In the view below the nut is partly tightened up.

Both spring beams – the large heavy Greenheart beams that run along the lower part of the face of the paddle boxes are being replaced, These are the parts that absorb the contact of the ship with piers. In the picture below the two old spring beams are seen on the quayside after removal from the ship.

The view below shows the new port side spring beam being prepared for fitting into the paddlebox. The vertical stanchions will support the decorative wooden paddle box facing (the part with the radial slots).

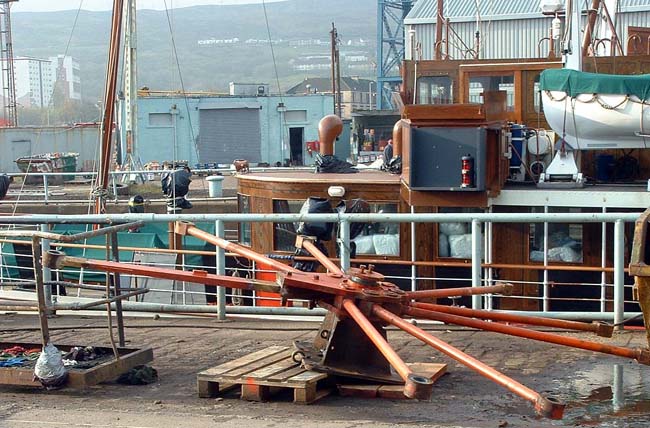

The structure shown in the picture below is the feathering gear of the port paddle wheel i.e. the equipment that controls the angle at which the paddle floats enter and leave the water and maximises the thrust developed by the paddle wheel. The central hub part is often called the ‘Star Centre’ or the ‘Jenny Nettles’. The ‘spokes’ are called the radius rods. It will be noticed that seven of the rods are tubular (circular cross section) and one is rectangular in cross section and considerably ‘heavier’ or stronger. This is the No 1 fixed rod that enables the feathering gear to be driven in the correct sequence with the paddle wheel. Being fixed, the paddle float attached to No 1 rod doesn’t enter the water at the optimum angle and produces a heavier ‘thud’ as it enters the water. This is the reason that 1 paddle beat of every 8 is louder than the remainder.

The next picture shows the starboard paddle wheel and feathering gear in place with one of the feathering radius rods fitted to a paddle float bracket near to the camera and running up to the Jenny Nettles at the top, centre of the picture. The bobbin of the paddle wheel is on the right. To make the feathering gear work the centre of the feathering gear i.e. its rotational axis must be eccentric to the rotational axis of the paddle wheel. Therefore, to ensure the optimum performance the paddle wheel it will be necessary to relocate the Jenny Nettles accurately on the spring beam (in this view the spring beam is obscured by a scaffold board).

A view into the port paddle box following the repainting of the inner surfaces and that part of Waverley’s hull that is not normally seen. The concrete blocks are providing temporary counterbalancing weight to offset that of the starboard wheel / shaft while the port side assembly is out of the ship.

While all the replacement work is going on in the port paddle box, repainting of the ship has been progressing as shown in the next two pictures – firstly of the hull is well advanced

And attention is turned to applying a fresh coat of paint to the ship’s famous funnels

Painting of the lower hull at the ship’s bow is complete. Some of the ships original riveted plating can be seen in the vicinity if the bow.

The port paddle box drum awaiting refitting after the wheel and paddle shaft.

Finally a dramatic view of the paddler from the floor of the dry dock looking back to the bow.